Shaping the Future.

CNC Systems

Globally Trusted.

Engineering Precision. Driving Progress.

At Automameccanico, we design and manufacture high-performance CNC machinery tailored for the wood, plastic, and aluminum processing industries. With a strong foundation in R&D and workshop-supported engineering, we deliver industrial-grade durability and precision — made in Türkiye, trusted worldwide.

Whether you're scaling production or upgrading your existing setup, our locally engineered solutions are designed to meet global standards. Backed by a dedicated support team and a commitment to innovation, we don't just build machines — we empower manufacturers.

Precision at Every Axis!

Automameccanico CNC Milling Machine is designed by the experienced team of Otoma Makine to process wood, plastic, aluminum and similar materials. The machine can be used for milling and surface processing applications with its standard features. It guarantees optimum results in your entry-level applications with its structure that combines quality and economy. It can be used in door processing applications with its additional options.

Precision at Every Axis!

Automameccanico CNC Milling Machine is designed by the experienced team of Otoma Makine to process wood, plastic, aluminum and similar materials. The machine can be used for milling and surface processing applications with its standard features. It guarantees optimum results in your entry-level applications with its structure that combines quality and economy. It can be used in door processing applications with its additional options.

Body Structure

The machine body is made of around 3850 kg, completely vibration-absorbed and stress-relieved steel. It allows for trouble-free production with its strong structure. The mechanical structure of the machine has been processed in a structure that can provide the highest level of precision and has passed through high-tech, precise control processes and tests.

Body Structure

The machine body is made of around 3850 kg, completely vibration-absorbed and stress-relieved steel. It allows for trouble-free production with its strong structure. The mechanical structure of the machine has been processed in a structure that can provide the highest level of precision and has passed through high-tech, precise control processes and tests.

Working Table Structure

The machine work table is made of HPL compact laminate material. The reference pistons positioned on the X and Y axes, which can be controlled via the CNC control unit, allow referencing with the highest level of precision. The work table is prepared in the matrix table type and is divided into equal blocks to ensure strong grip. The work table has a four-zone vacuum area as standard. Vacuum areas can be increased according to customer demand.

Working Table Structure

The machine work table is made of HPL compact laminate material. The reference pistons positioned on the X and Y axes, which can be controlled via the CNC control unit, allow referencing with the highest level of precision. The work table is prepared in the matrix table type and is divided into equal blocks to ensure strong grip. The work table has a four-zone vacuum area as standard. Vacuum areas can be increased according to customer demand.

Axis Movements

The X and Y axes of the machine are designed with high quality ground rack and pinions for precise positioning and high speed operation. All axes are driven by brushless high-tech servo motors that guarantee excellent acceleration.

Axis Speeds: X-Y Axis nominal speed 47.1m/min max speed 94.2, Z Axis Nominal speed15m/min Max speed 30m/min

It can work at high speeds with the tool path controlled by the axis drivers.

The machine has the capacity to process at high precision and speeds with the help of faster data transfer.

Automatic Tool Length Measuring Unit

With the help of the control unit, the tools held on the machine can be automatically measured and recorded on the system. The automatic tool length measurement feature is used to measure tools up to 120 mm diameter.

Automatic Tool Length Measuring Unit

With the help of the control unit, the tools held on the machine can be automatically measured and recorded on the system. The automatic tool length measurement feature is used to measure tools up to 120 mm diameter.

Central Lubrication Unit

The machine has a central lubrication system that can provide precise lubrication at 13 different points. The oil used on the system contributes to the longer life of the mechanical parts and reduces maintenance costs. The system also allows manual lubrication via the control unit.

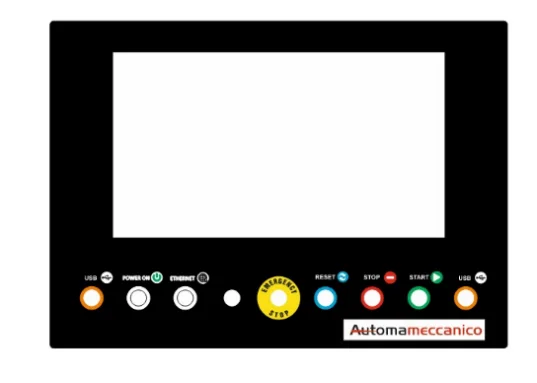

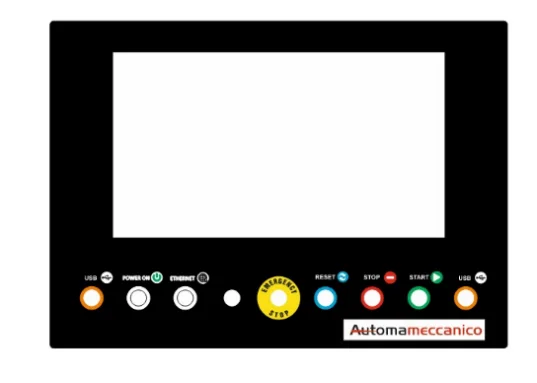

CNC Control Unit Features

Professional series ISAC control unit is used to control the machine axes. An industrial computer with a Windows-based operating system is used on the control unit, which allows trouble-free operation under the most difficult conditions.

ISAC CONTROL UNIT FEATURES

The operating system works with G codes. Thanks to the precise interpolation of all axes, the control unit allows perfect control of the axes. With the easy-to-use and high-performance interface, all functions can be controlled on a single screen. The simulation of the work being cut on the machine can be controlled. An unlimited number of work lists can be created on the interface. Changes can be made between the work lists.

- Windows based operating system

- 21.5’’ TFT color LCD screen

- Integrated Ethernet port

- USB port

- Remote control feature

- User friendly easy interface

ISAC CONTROL UNIT FEATURES

The operating system works with G codes. Thanks to the precise interpolation of all axes, the control unit allows perfect control of the axes. With the easy-to-use and high-performance interface, all functions can be controlled on a single screen. The simulation of the work being cut on the machine can be controlled. An unlimited number of work lists can be created on the interface. Changes can be made between the work lists.

- Windows based operating system

- 21.5’’ TFT color LCD screen

- Integrated Ethernet port

- USB port

- Remote control feature

- User friendly easy interface

ISAC CONTROL UNIT FEATURES

The remote connection feature on the system allows remote connection to the machine from anywhere with an internet connection. It is supported full-time, especially after sales.

ISAC CONTROL UNIT FEATURES

The remote connection feature on the system allows remote connection to the machine from anywhere with an internet connection. It is supported full-time, especially after sales.

MODELS

BASISTRIA – 3 Axis Machining Center

Adapted in two chassis sizes 2137 and 2128

BASISQUATTOUR - 4 Axis Machining Center

Adapted in two chassis sizes 2137 and 2128

BASISQUINQUE - 5 Axis Machining Center

Adapted in two chassis sizes 2137 and 2128

Hiteco Motor

(8,5-11 kW)

The machine has a 8.5 - 11 kW Hiteco spindle motor depending on the need. The spindle motor allows for excellent results in milling applications including 3D processing. The system works integrated with the progressive piston bellows. The bellows level is automatically controlled according to the tool information from the program.

Hiteco Motor (8,5-11 kW)

The machine has a 8.5 - 11 kW Hiteco spindle motor depending on the need. The spindle motor allows for excellent results in milling applications including 3D processing. The system works integrated with the progressive piston bellows. The bellows level is automatically controlled according to the tool information from the program.

29L0082089A twin F63 Hiteco Aggregate

According to the need, Hiteco Aggregate unit is used for door lock hinge location processing and other types of side processing applications in BASISTRIA models. With ER25 connection type and double output, side processing applications can be carried out precisely.

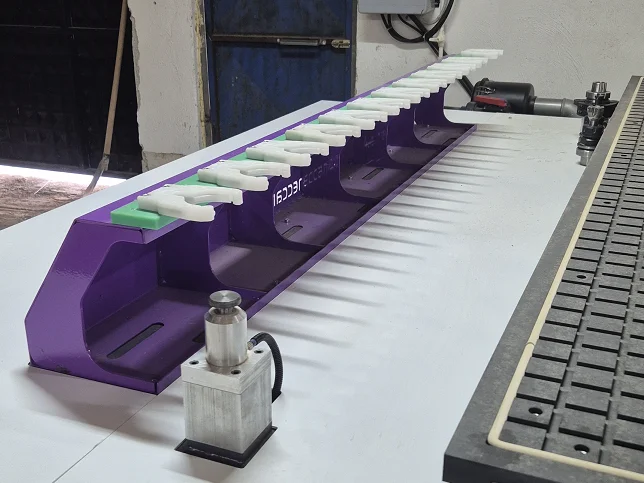

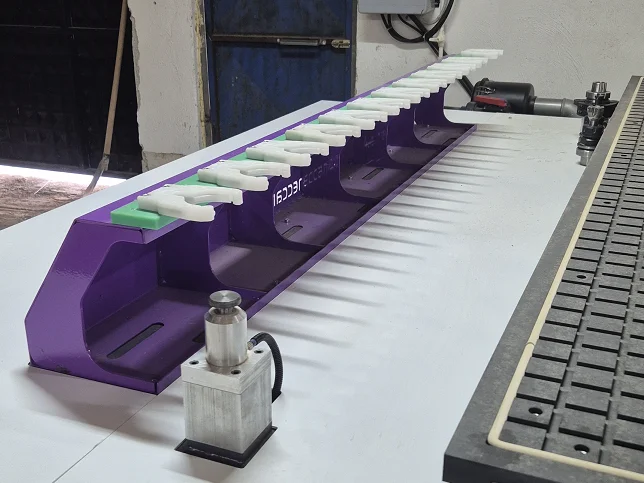

Fixed Magazine Unit (12 tools)

The machine has a fixed tool change unit with a capacity of 12 tools. The unit is located at the rear of the machine body. Tools up to a maximum diameter of 180 mm can be held ready for machining on the magazine. Special tools such as Aggregate can also be used on the system. High quality holders allow fast and precise tool changes during tool pick-up and drop-off operations.

Fixed Magazine Unit (12 tools)

The machine has a fixed tool change unit with a capacity of 12 tools. The unit is located at the rear of the machine body. Tools up to a maximum diameter of 180 mm can be held ready for machining on the magazine. Special tools such as Aggregate can also be used on the system. High quality holders allow fast and precise tool changes during tool pick-up and drop-off operations.

Eurovac 250 m³ Vacuum Pump

The machine uses a Eurovac 250 m³/h 5.5 kW 8.9HP capacity dry type vacuum pump. The latest technology vacuum pump allows for high precision processing with maximum retention. The unit allows for long years of operation with low maintenance and operating costs.

HMI-Turkish Interface and Computer Numerical Control

The new HMI interface developed by our company's software engineers enables easy use in production. Its visually supported structure provides ease of use. With its advanced system structure and the option of use in different languages, it offers a suitable infrastructure for customers all over the world.

SYNTEC E01-ST4012ME-A Series numerical CNC panel is an interface that manages all functions and movements of the machine with numerical data and commands. It works entirely with numerical (digital) data instead of analog controls.

HMI-Turkish Interface and Computer Numerical Control

The new HMI interface developed by our company's software engineers enables easy use in production. Its visually supported structure provides ease of use. With its advanced system structure and the option of use in different languages, it offers a suitable infrastructure for customers all over the world.

SYNTEC E01-ST4012ME-A Series numerical CNC panel is an interface that manages all functions and movements of the machine with numerical data and commands. It works entirely with numerical (digital) data instead of analog controls.

Handwheel Unit

The handwheel is used to control the machine axes in manual mode outside the control panel. The machine axes and operating speeds can be controlled on the handwheel.

Vacuum Zones Control

A regional vacuum system developed by our company engineers without leaving it to the operator's initiative. The control system operates the relevant vacuum zones according to the table sizes to be processed, thus providing a strong vacuum effect even when processing small tables. The working table can be easily optimized during processing by means of vacuum zones created in accordance with different plate sizes.

Vacuum Zones Control

A regional vacuum system developed by our company engineers without leaving it to the operator's initiative. The control system operates the relevant vacuum zones according to the table sizes to be processed, thus providing a strong vacuum effect even when processing small tables. The working table can be easily optimized during processing by means of vacuum zones created in accordance with different plate sizes.

Servo Motors

In reinforced special series, X-Y-Z Axis motors are Syntec S08-AM8-40-F3 F series "AM 1.7 kW Motor", Rated Speed (rpm) 2000, Max. Speed (rpm) 4000, Rated Torque (Nm)8.34, Max. Torque (Nm) 30.8, Servo motors manufactured for high powers.

X-Y-Z Axis motors in standard series, Syntec S08-AM4-40K-H3 H series "AM 1 kW Motor", Rated Speed (rpm)2000, Max.Speed (rpm)4000, Rated Torque(Nm)4.7, Max.Torque(Nm)14.1, Servo motors manufactured for high powers.

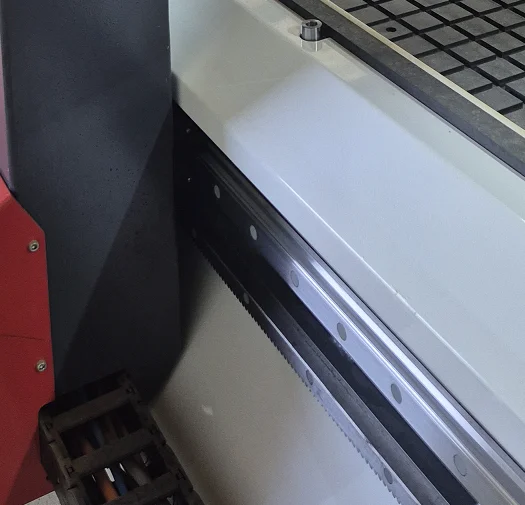

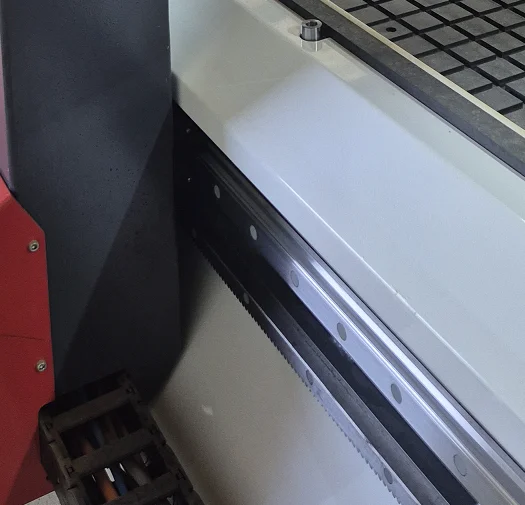

Linear Guides and Carriages

On the X axis, 35 mm rail and carriage systems are used with high carrying capacity and rigidity, durable strength, on the machine. On the Y axis and Z axis, 25 mm rail and carriage systems are used, and Schneeberger or Staff is used as the product brand.

Linear Guides and Carriages

On the X axis, 35 mm rail and carriage systems are used with high carrying capacity and rigidity, durable strength, on the machine. On the Y axis and Z axis, 25 mm rail and carriage systems are used, and Schneeberger or Staff is used as the product brand.

Planetary Reducer

Gear ratios are chosen according to the area the customer will use, and Liming is used as the product.